Forging manufacturing is vital throughout numerous industries because of its ability to supply high-power metallic additives vital for important programs. Its versatility makes it necessary in sectors consisting of aerospace, automotive, and heavy machinery, where additives have to resist severe situations. The process allows for the production of parts with advanced mechanical houses, including greater energy, sturdiness, and fatigue resistance.

Forging’s sizeable use is attributed to its capability to optimize material properties and overall performance, making sure that additives are reliable and safe. Great manipulation is critical to this versatility, as it ensures that every forged component meets stringent specifications and industry standards, thereby improving the overall performance, reliability, and safety of forging manufacturing process. This pliability and emphasis on pleasantness contribute to forging’s enormous utility and importance in present-day production.

The Importance of Quality Control in Forging Manufacturing

This article delves into the significance of quality management in forging manufacturing, exploring its effect on product quality, value, and typical performance.

Ensuring Consistency and Reliability

One of the number one goals of satisfactory manipulation in forging production is to ensure consistency and reliability in the completed products. Forged components are frequently subjected to intense situations and ought to meet stringent overall performance requirements. Exceptional control measures, consisting of regular inspections and checking out, help verify that each element conforms to the specified design parameters and tolerances.

Minimizing Defects and Failures

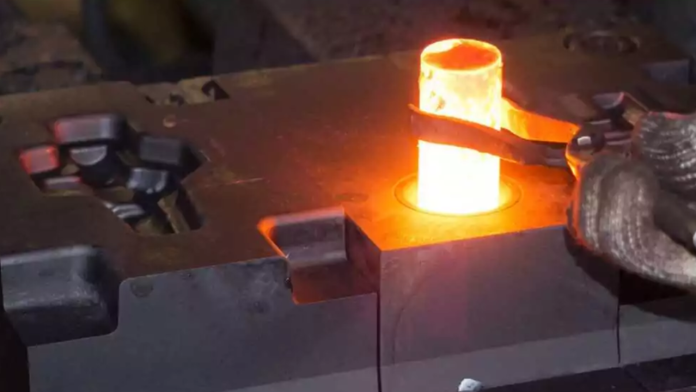

Excellent control is instrumental in minimizing defects and failures in cast components. The forging procedure involves high temperatures and massive strain, which could lead to diverse defects if not cautiously monitored. Common troubles consist of internal voids, surface cracks, and dimensional inaccuracies. Implementing rigorous first-rate control methods enables us to become aware of and deal with those defects early in the production process, lowering the risk of component failure and the related costs of remodeling or replacement.

Enhancing Component Performance

Forged components are valued for their superior mechanical properties, consisting of energy, toughness, and fatigue resistance. Great control performs a critical function in making sure that those residences are performed constantly across all produced parts. By conducting thorough inspections and tests, including hardness checking, tensile checking, and microstructural evaluation, producers can verify that the additives meet the specified performance standards. This complements the general reliability and toughness of the additives, contributing to higher performance in their supposed applications.

Reducing Production Costs

At the same time, exceptional management entails an in-advance investment in testing and inspection, which in the end contributes to cost savings. By stopping defects and making sure that the most effective notable components are produced, producers can lessen the prices associated with transform, scrap, and assurance claims. Moreover, quality control allows for optimizing the forging process, enhancing fabric usage, and lowering waste. This not only effectively lowers production expenses but also helps create more sustainable production practices.

Improving Customer Satisfaction

Quality forged components make contributions to purchaser satisfaction through assembly or exceeding expectations for overall performance, reliability, and durability. Great manipulation allows for making certain that every component adheres to the agreed-upon specifications and requirements, reducing the likelihood of client lawsuits and returns. Happy customers are much more likely to become repeat buyers and recommend the producer to others, which could cause extended business opportunities and a boom.

Supporting Continuous Improvement

High-quality management is not a static method but a dynamic and ongoing one that supports continuous improvement in forging production. By systematically studying statistics from inspections and exams, manufacturers can identify developments and regions for improvement. These statistics can be used to refine the forging process, enhance material satisfactorily, and put into effect high-quality practices. Non-stop improvement efforts contribute to better average product and operational efficiency, helping manufacturers live competitively in a rapidly evolving industry.

Summary

Quality control is indispensable to forging production, impacting everything in the production procedure and the final product. It ensures consistency and reliability, minimizes defects and disasters, complements issue performance, reduces production expenses, and helps compliance with industry standards. Moreover, fine management contributes to purchaser delight, continuous development, and protection. By implementing robust quality control measures, forging producers can deliver outstanding components that meet the demands of their customers and the requirements of their industries.